AI-enabled Vision Inspection and Automation Suite

The suite leverages advanced image processing and machine learning algorithms to provide quality assurance at the assembly line.

How Optivity® Works

Optivity® is an AI-enabled Vision Inspection and Automation Suite powered by our vision controller (DEEPCATCH). It runs surface inspection algorithms on surfaces of various materials and detects anomalies otherwise not discernible by the human eye.

What Optivity® Offers

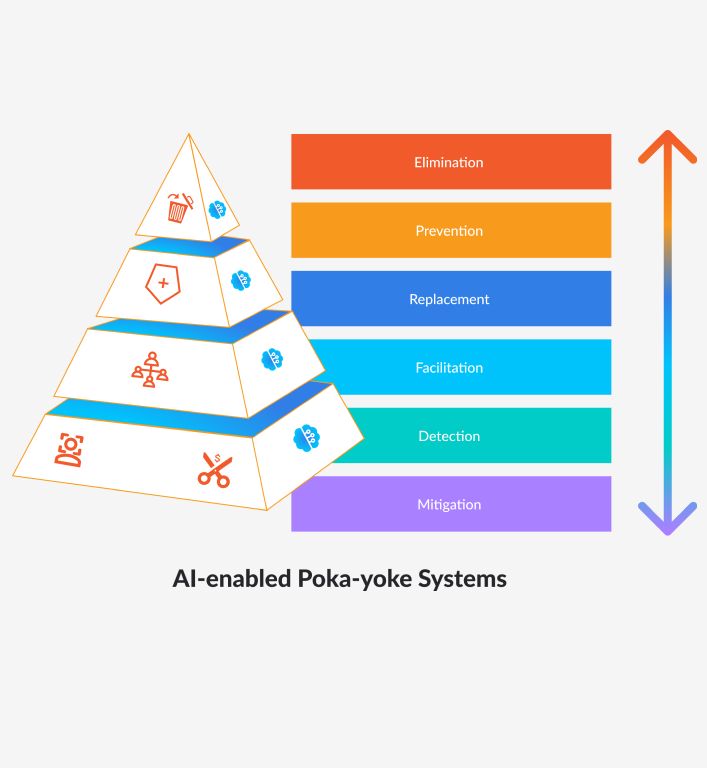

OPTIVITY® creates actionable intelligence by using deep learning algorithms. It analyses spatial and sequential data. OPTIVITY® detects abnormalities in the manufacturing process using AI-enabled Poka-yoke systems.

Features of Optivity®

Compact

The solution combines the utility of PC and PLC to facilitate a compact and robust solution.

Vision and Sensors

Connect to 6 cameras at once. Uses UART Communication protocol to connect with multiple sensors. Monitors numerous aspects such as proximity, temperature, radiation, etc.

Edge – AI-Enabled

The solution runs complex deep learning algorithms on edge without the cloud, thus maximizing output at consistent quality. The Edge inference ensures data privacy and security for sensitive applications.

Integrated

The collected data can be linked externally to multiple protocols for efficient data accumulation and cataloging through various APIs.

Applications of Optivity®

Optivity® is used for consistent performance with the help of machine learning algorithms to ensure high repeatability and high-quality throughput.

Tracking

- Optical Character Recognition (OCR)

- Printed/ Engraved/ Embossed

- Line/Bar codes

- QR/Data Matrix codes

Surface Inspection

- Print inspection

- Surface defects

- Paint Inspection

- Colour Passivation

Automation

- Sealant application

- Palletization

- Conveyorized optimal flow

Why Optivity®

Industry 4.0 enabled Optivity® offers a lot of benefits to make your assembly line trouble-free, automating it by detecting and rectifying defects to increase throughput and efficiency.

-

Eliminates subjectivity in Quality Inspection

Eliminates subjectivity in Quality Inspection

-

Internet-enabled Data Logging (Deepcatch)

Internet-enabled Data Logging (Deepcatch)

-

Advanced machine learning algorithm locates, traces, and accounts for the exact error

Advanced machine learning algorithm locates, traces, and accounts for the exact error

-

Scalable, Customizable, Fast, and Precise

Scalable, Customizable, Fast, and Precise

-

Dashboards, KPIs for decision making

Dashboards, KPIs for decision making

-

Direct Hardware Triggers (without PLC)

Direct Hardware Triggers (without PLC)

-

Easy to operate and can be monitored by unskilled labor

Easy to operate and can be monitored by unskilled labor

The Phoenix Group™ Homepage

The Phoenix Group™ Homepage